When it comes to car maintenance, I’m sure the most familiar of all is the oil change, because whether a car is new or of a certain age, after a certain period of time or a certain number of kilometers it will need to be changed at an Automobile Sales Servicshop, an oil change center, a comprehensive garage or an express repair and maintenance shop.

However, the amount of oil filled varies from one engine to another and, paradoxically, lubricant manufacturers use 1 L and 4 L packs as the main form of packaging, which undoubtedly results in unjustified waste of lubricants and increases the pressure to deal with environmental issues at a later stage. In this context, centralized oil supply systems are all the rage due to their centralized management, precise control, cost reduction, and efficiency, as well as their green credentials.

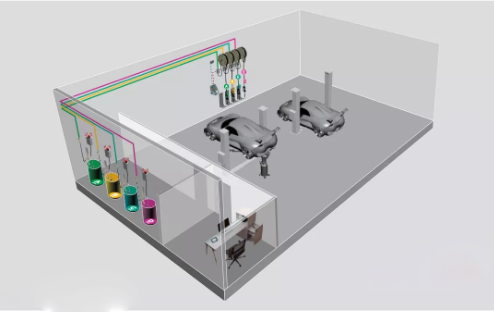

Overview and composition of the centralized Oil Management System(oil supply system)

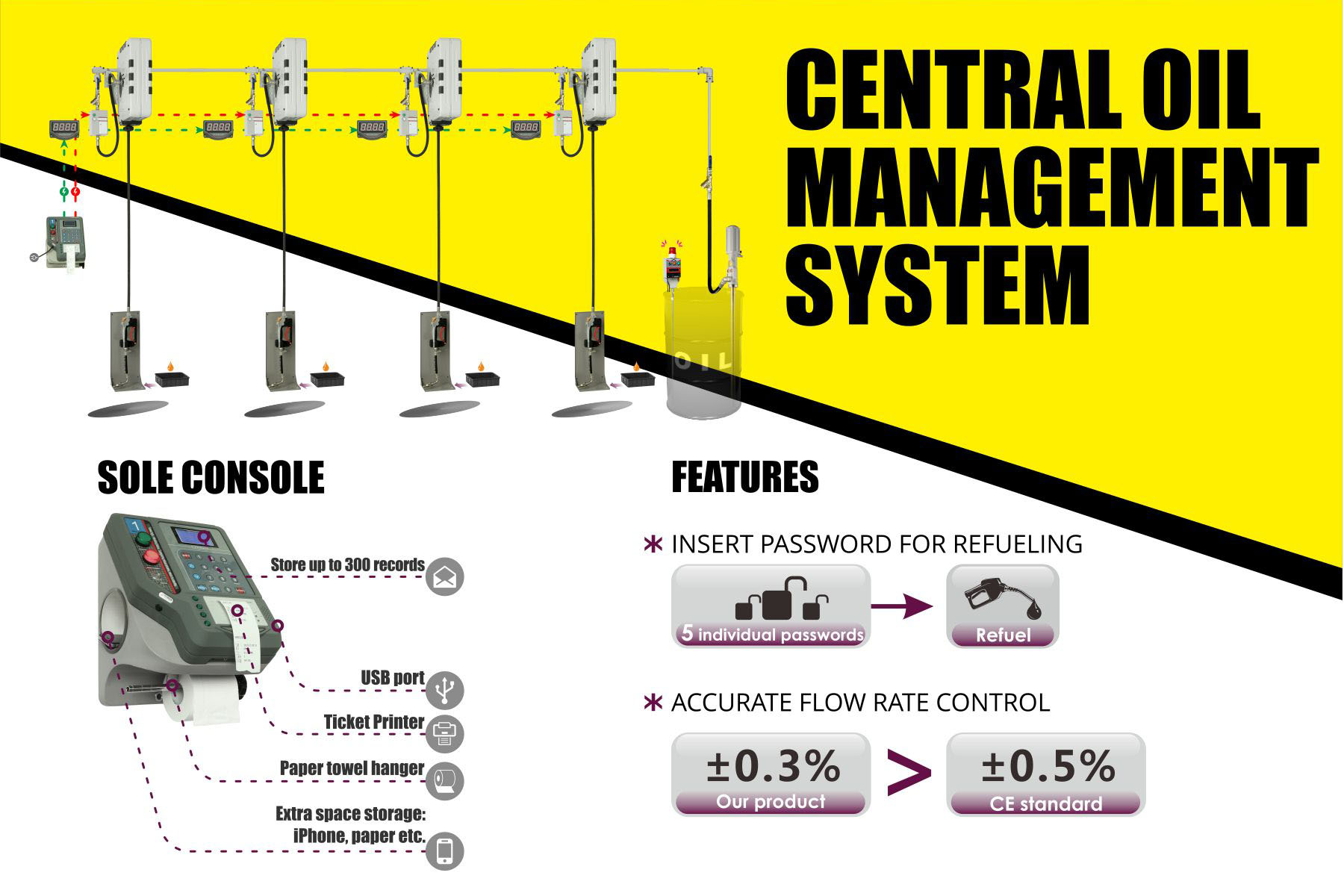

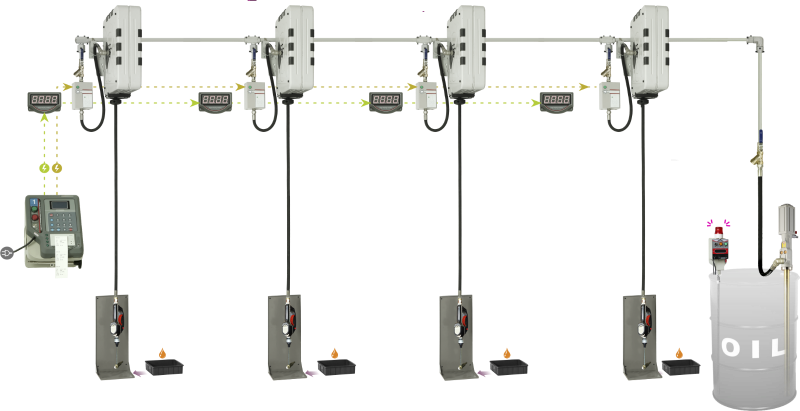

The centralized lubrication oiling system is an oiling system in which the lubricating oil is placed centrally in the depot, using compressed air as power to drive the reciprocating movement of the plunger pump, which is connected by a high-pressure resistant oil pipeline and transported to each refueling point. It is possible to refill a variety of oils at the same time and to refill multiple refueling points. It forms a unified whole with centralized oil storage, centralized transport, and centralized management.

A complete centralized oil supply system usually includes an oil storage drum (usually provided by the lubricant manufacturer), a low-level automatic stop device, a pneumatic thin oil pump, a thin oil pump connection pipe, a mains inlet filter valve set, a high-pressure resistant oil delivery line, a branch inlet filter valve set, a flow control solenoid valve, a hose reel, an oil filling gun, an anti-drip oil connection box, and a system master control and oil and water filter.

1. System master controller.

The main control unit is not only the window of human-machine interaction for the operator or warehouse manager but also the brain of the whole centralized oil supply system. A reasonable main controller must be matched with a high-precision electronic induction flow valve to achieve precise refueling, no more refueling, and no leakage; it can set the operation login password, work order number, oil code, and other information to facilitate management; it supports data query, modification and printing functions; it should also be able to dynamically display the working status and view the single and cumulative refueling quantity, etc.

2. Pneumatic thin oil pump (pumping pump/oil transfer pump)

In order to meet the requirements of different working conditions and adapt to the transmission of different distances, a suitable pumping pump should be selected. The common ratio pump is 1:1, 3:1, and 5:1, respectively for a short distance, less than 50M, and more than 50M transmission paths. The rule is that the greater the ratio of the pump, the greater the delivery pressure, and the further the transmission path, the smaller the terminal output flow will be.

3. Oil and water filter lubricator & regulator set (3-piece)

The inlet end of the pneumatic oil pump should be equipped with an oil and water filter and a regulator pump to effectively filter the water in the air source, adding special lubricant for the oil pump can extend the life of the oil pump and ensure pumping efficiency, and by adjusting the pressure valve the oil pump can work under different pressure environments to ensure the smooth completion of refueling operations.

4. Filter valve assembly

In order to avoid the impurities in the thin oil from clogging the flow solenoid valve and oil filling gun and other precision devices, the installation of filter valve components is particularly important.

5. Flow, sensor controller,

Flow control solenoid valve oil flow meter and flow switch together, on the one hand, to accurately measure the amount of oil delivery, on the other hand as an electronic switch valve, is a kind of electronically controlled actuator.

6. LED high-level display

LED high-level refueling volume display, easy to view the refueling status from a distance, so that customers know whether the car refueling volume is accurate, and record the last refueling volume.

7. Fuel station oil circuit winder (open & closed)

In order to improve the overall image of the entire maintenance workshop, the winder can also be installed in the N-in-one combination drum. When selecting a winder, attention should also be paid to the smoothness of its locking and automatic recovery functions.

8. Low-level automatic stop device

In order to avoid frequent visits to the depot to check the amount of oil stored in the storage drum, a basic centralized oil supply system, when the oil in the drum is too low, the system should be able to automatically cut off the oil pump air source and sound and light alarm to remind the depot management, to avoid inaccurate fuel metering due to the oil pump emptying the pipe into the air.

9. Nozzle

As a fuel delivery terminal, there are digital flows and countless flows, it is recommended to purchase a fuel gun with a digital display function.

10. Fluid piping (oil piping)

Fluid piping is best to use seamless steel pipes, considering the convenience of on-site installation and later maintenance, should be combined with special pipe joints, to ensure the quality of installation, but also require the overall aesthetics. It is recommended to choose a professional company to complete the installation. For specific installation considerations, see “What are the key points of installation of oil piping for centralized oil supply systems?

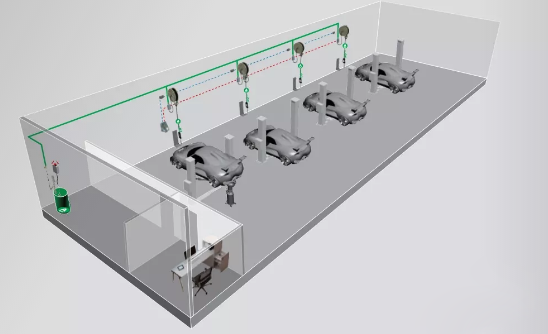

After introducing the composition and working principle of the centralized oil supply system, what we are looking forward to is the configuration scheme.

Program one: 1 oil type; 4 refueling branches; 8 refueling stations (one branch covers two stations)

Corresponding fixed configuration list: 1 main control machine + 1 oil pump + 1 set of low level automatic monitoring device + 1 set of oil pump connection hose + 1 set of inlet filter valve set + 4 sets of outlet filter valve set + 4 flow control valves + 4 hose reels + 4 high-level LED display + 4 oil filling guns + 4 sets of anti-drip oil connection boxes

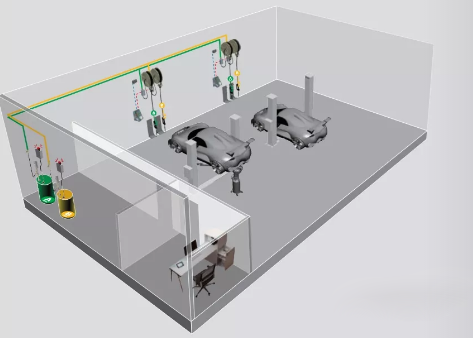

Scheme 2: 2 types of oil; 2 branches of each type; 4 refueling stations (one branch covers two stations)

Corresponding fixed configuration list: 1 main control machine + 2 oil pumps + 2 sets of low-level automatic monitoring devices + 2 sets of oil pump connection hoses + 2 sets of oil inlet filter valve sets + 4 sets of oil outlet filter valve sets + 4 flow control valves + 4 hose reels + 4 high-level LED displays + 4 oil filling guns + 4 sets of drip-proof oil connection boxes

Scheme 3: 4 types of oil; 1 branch for each type; 2 refueling stations (one branch covers two stations)

Corresponding fixed configuration list: 1 main control machine + 4 oil pumps + 4 sets of low-level automatic monitoring devices + 4 sets of oil pump connection hoses + 4 sets of oil inlet filter valve sets + 4 sets of oil outlet filter valve sets + 4 flow control valves + 4 hose reels + 4 high-level LED displays + 4 oil filling guns + 4 sets of drip-proof oil connection boxes

Option 4: 1 oil product for the simple version; 4 branch circuits; 8 refueling stations (one branch circuit covers two stations)

Corresponding fixed configuration list: 1 oil pump + 1 set of low-level automatic monitoring devices + 1 set of oil pump connection hoses + 4 sets of inlet filter valve sets + 4 sets of outlet filter valve sets + 4 hose reels + 4 oil filling guns (must be equipped with a digital display fuel gun) + 4 sets of drip-proof oil connection boxes

The centralized oil supply system for car repair workshops is a systematic project, belonging to the workshop engineering series, from system selection, and configuration to installation and commissioning, the professionalism is extremely high, and the installation of high-quality products by non-professional companies and non-professional technicians will lead to frequent failures at a later stage, such as oil leakage, or paralysis of the whole system. We specialize in the continuous export of total solutions to the automotive aftermarket and are your choice for the construction of centralized oil supply systems.